Moderne, automatisierte Industrieanlagen sind heutzutage ein entscheidender Wettbewerbsvorteil.

Sie haben viele Prozesse, die mühsam von Hand erledigt werden müssen?

Mittels Fertigungsautomatisierung ist es möglich diese völlig automatisch ablaufen zu lassen – und zwar ohne in neue teure Maschinen investieren zu müssen. Dies steigert die Produktivität und verringert das Investitionsvolumen in Ihrem Unternehmen.

Durch diese Art der Prozessautomatisierung verbessern Sie zudem die Qualität Ihrer Werkstücke und verringern Ihre Taktzeiten. Anhand digitaler Überwachung wissen Sie stets, wie produktiv Ihre Prozesse laufen und können diese am PC steuern.

Die Verfügbarkeit Ihrer Maschinen steigt durch unsere Lösungen. Versprochen! Sie brauchen messbare Ergebnisse?

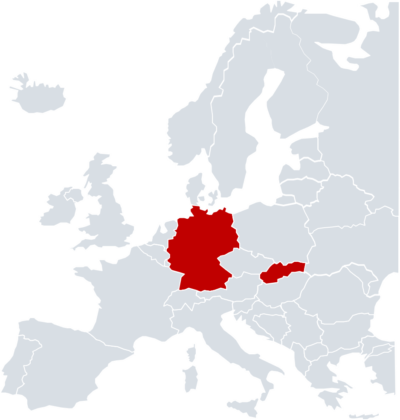

Wir bieten Ihnen Qualität und Maschinenexpertise aus Neumünster.

Unsere Leistungen auf einen Blick:

PINFLOW Entgrattechnologie

Das Entgratsystem für Ihre Anforderungen.

gründlich – schnell – wirtschaftlich

Lohnentgraten

Unser flexibler Service für Sie, wenn sich für Sie die Investition in ein Entgratsystem nicht lohnt.

Automatisierungslösungen

Halten Sie Ihre Produktion fit, damit Sie im Wettbewerb bestehen können.

Sicherheitstechnik / CE

Sicherheitssysteme für den Neuanlagenbau und bestehende Konstruktionen.

Steuerungserweiterung / Maschinenumfeld-Systeme

Wir sind „item-pluspartner“ und entwickeln für Sie die passenden Lösungen für Ihr Maschinenumfeld

PINFLOW Entgrattechnologie

Das Entgraten von Werkstücken gewinnt an Bedeutung. In den letzten Jahren wurde die Leistungsfähigkeit der spanerzeugenden Verfahren wesentlich erhöht. Gleichzeitig wird jedoch häufig noch mit der gleichen Methode wie vor Jahrzehnten entgratet.

Dabei stellt gerade der Entgratarbeitsgang hohe Anforderungen an Qualität und Prozesssicherheit, um bei den heutigen hoch organisierten Fertigungsstrukturen und immer komplexer werdenden Werkstücken kostengünstig und qualitativ hochwertig fertigen zu können. Hier bietet sich das PINFLOW-Verfahren als eine innovative Alternative zu anderen Verfahren besonders an.

Lohnentgraten

Nicht immer lohnt sich die Investition in ein effektives Entgratsystem. Zum Beispiel, wenn die Stückzahlen der entsprechenden Werkstücke gering sind und sich keine sinnvollen Amortisationszeiten ergeben.

Daher bieten wir Ihnen die Möglichkeit, Ihre Werkstücke auf unserer PINFLOW-Anlage in Neumünster kostengünstig, schnell und präzise bearbeiten zu lassen. Senden Sie uns einfach einige Musterteile oder Zeichnungen, anhand derer wir Ihnen dann ein unverbindliches Angebot unterbreiten.

Automatisierungslösungen

Bei der Planung von Produktionsanlagen wird das Hauptaugenmerk häufig auf die Fertigungsprozesse gelegt, während der Werkstücktransport vernachlässigt wird. In der Praxis zeigt sich dann sehr schnell, dass die Taktzeit durch den manuellen Transport leidet und die Stückkosten höher liegen als geplant.

Hier kann mit einfach gestalteten und kostengünstigen Be- und Entladesystemen oder Verkettungssystemen Abhilfe geschaffen werden. Durch einen automatisierten Werkstücktransport werden außerdem Beschädigungen minimiert und die Integration von Messstationen wird ermöglicht. Darüber hinaus werden Maschinenstillstände aufgrund falsch eingelegter Werkstücke vermieden.

Sicherheitstechnik / CE

Neben der Funktionalität einer Anlage ist ein weiterer entscheidender Faktor die Sicherheit, welche entsprechenden Standards genügen muss. Sie als Betreiber einer Anlage, sind nach der Maschinenrichtlinie dafür verantwortlich, dass ebendiese den grundlegenden Sicherheits- und Gesundheitsschutzanforderungen genügt. Häufig fällt die Auslegung ausreichender Maßnahmen für eine Maschine sehr schwer.

Hierbei unterstützen wir Sie gern.

Steuerungserweiterung / Maschinenumfeld-Systeme

Ob höhenverstellbare Arbeitstische zum ergonomischen Arbeiten, Treppen und Podest-Systeme zum besseren Erreichen schwer zugänglicher Bereiche, Maschinenkabinen zum Schutz sensibler Technik oder auch Regalsysteme zur optimalen Lagerung wichtiger Komponenten Ihres Arbeitsablaufes.

In Zusammenarbeit mit item (Weltmarktführer bei Systembaukästen für industrielle Anwendungen) entwickeln wir die für Sie optimale Lösung.

Als zertifiziertes Unternehmen nach DIN ISO 9001 und dem Sicher mit System Gütesiegel sind wir stets bestrebt, Ihnen ein breites Produktsortiment anzubieten, das alle Ihre Anforderungen erfüllt.

Jetzt Kontakt aufnehmen

Stefan Ihms

Bereichsleiter

2K Maschinenbau GmbH

Krokamp 35 · 24539 Neumünster

Fon +49. 4321. 85444 0

vertrieb@2kservice.de

2K Maschinenbau GmbH

ein Unternehmen der 2K Unternehmensgruppe

Navigation

Service

Rechtliches